- 2/11/2019

- TWS Houston

- 2/8/2019

- TWS Jacksonville

- 2/8/2019

- TWS Jacksonville

- 2/8/2019

- TWS Houston

- 11/30/2018

- TWS Tulsa

- 11/11/2018

- TWS Jacksonville

- 10/21/2018

- TWS Tulsa

- 10/20/2018

- TWS Tulsa

- 10/20/2018

- TWS Jacksonville

- 10/19/2018

- TWS Tulsa

- 9/6/2018

- TWS Tulsa

- 9/6/2018

- TWS Houston

- 9/6/2018

- TWS

- 9/6/2018

- TWS Tulsa

- 7/17/2018

- TWS Jacksonville

- 7/3/2018

- TWS Tulsa

- 6/30/2018

- TWS Tulsa

- 6/30/2018

- TWS Tulsa

- 5/11/2018

- TWS Tulsa

- 5/8/2018

- TWS Jacksonville

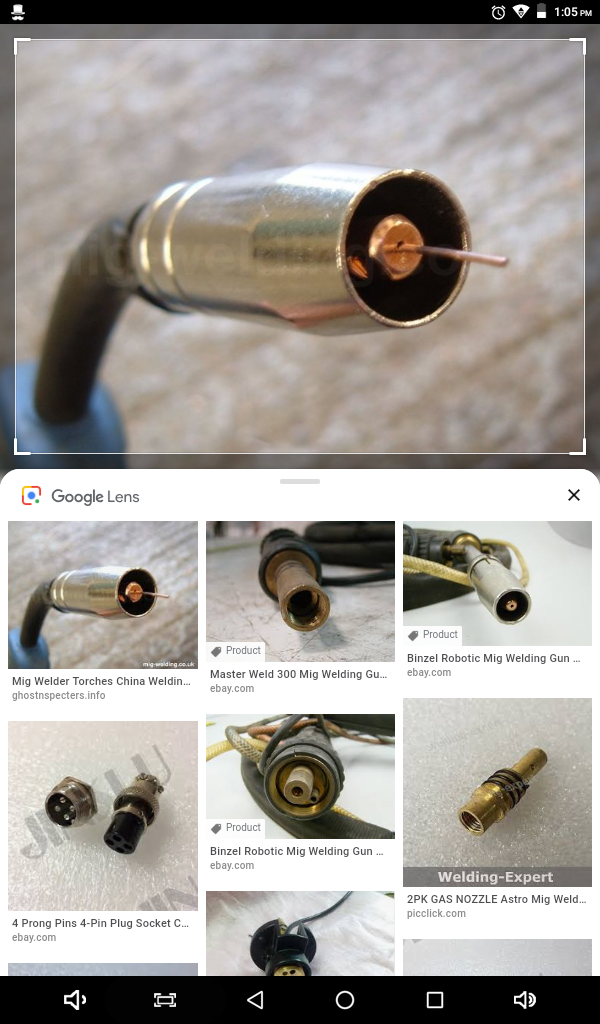

Luiscantu

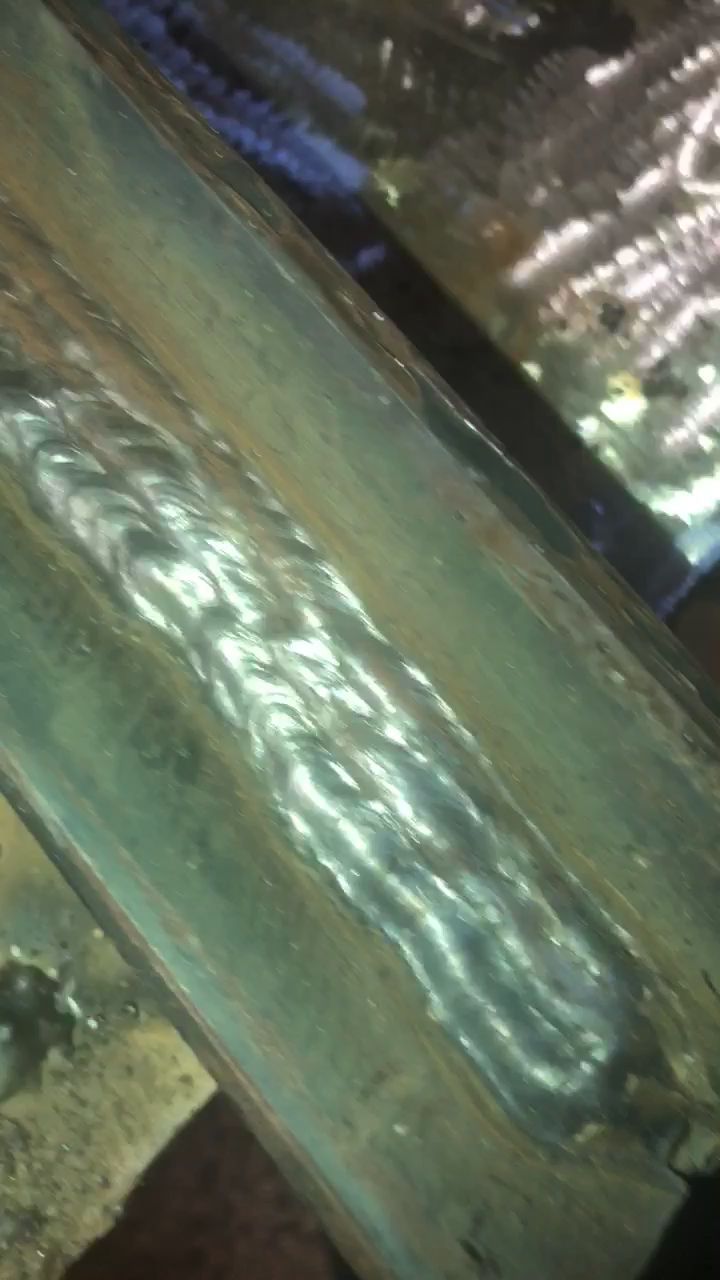

I am excited to show this 4f weld , this weld means a great deal being that I’ve never welded in the the past and to be able to show this is awesome . I have successfully completed all 6 weld test for class 101 in 3 weeks and look forward to continuing this amazing work . Hard work and long hours in the shop made this possible.

Thanks

Andrew Frederickson

Saved money for 2 years to for tuition and living expenses and to move 1500 miles from home to go to this school. Probably my most risky but rewarding decisions to date. Never been so proud as I was when I earned “Top One” and managed to do it twice by phase 6!

Ryan White

I’m most proud of my class and my mentor jimmy. Jimmy is an amazing teacher and a even more amazing person to talk too. He’s changed my view of how to weld properly and helped improve my welding by a long shot. Jimmy isn’t like most teachers and tell you and then sit around. He’ll go booth to booth and check up and give you tips on how to improve your welds.

Derek Dolan

I am proud of myself because my instructor Luis always pushes me and tells me I can do it and I keep that in the back of my mind as I am welding, the obstacle I had to overcome was not having the confidence to believe in myself that’s where Luis came in now I can run micro beads while smiling under my welding hood, just because he believed in me and that was enough for me to achieve and completely master the concept

Caleb Rainey

I have several pictures that I submitted I am proud of my overall self improvement. I have worked hard and busted my tail, from early morning around 7:30 until 5:30-6:00 in the evening most days. Especially when I’m having trouble with a weld in lab, and like they say, practice does make perfect, or atleast close enough!

Lauren King

This was my 4th or 5th time doing 6g MIG and Flux core. It taught me a lot about controlling the weld and how much gravity can affect the weld puddle. The hardest thing about this was trying to find a position where I could not only weld but see what I was doing. This whole thing was a challenge.

Caleb Rainey

I am most proud of my horizontal T-Plate welds. I am very proud of these because I had a little trouble place the welds in the right positions to make the finished project come out flat and I gradually got better and better the more I done it. I eventually ended up having very consistent, well placed, very flat, and pretty welds! I am very proud to call myself a TWS student! The instructors have been helpful and very informative. I see myself getting better and better each and every weld. I have been working hard and I see a bright future for me as long as I keep up the hard work!

Alex Zwego

Most proud of sticking with it and learning all the different techniques, the Tig Weld i had heard was one of the hardest to learn and that seemed to be one of the more easier to learn for me. I look forward to graduating and getting a good job. I want to take this time to thank all the instructors that have helped me along the way.

Thank you

Alex Zwego

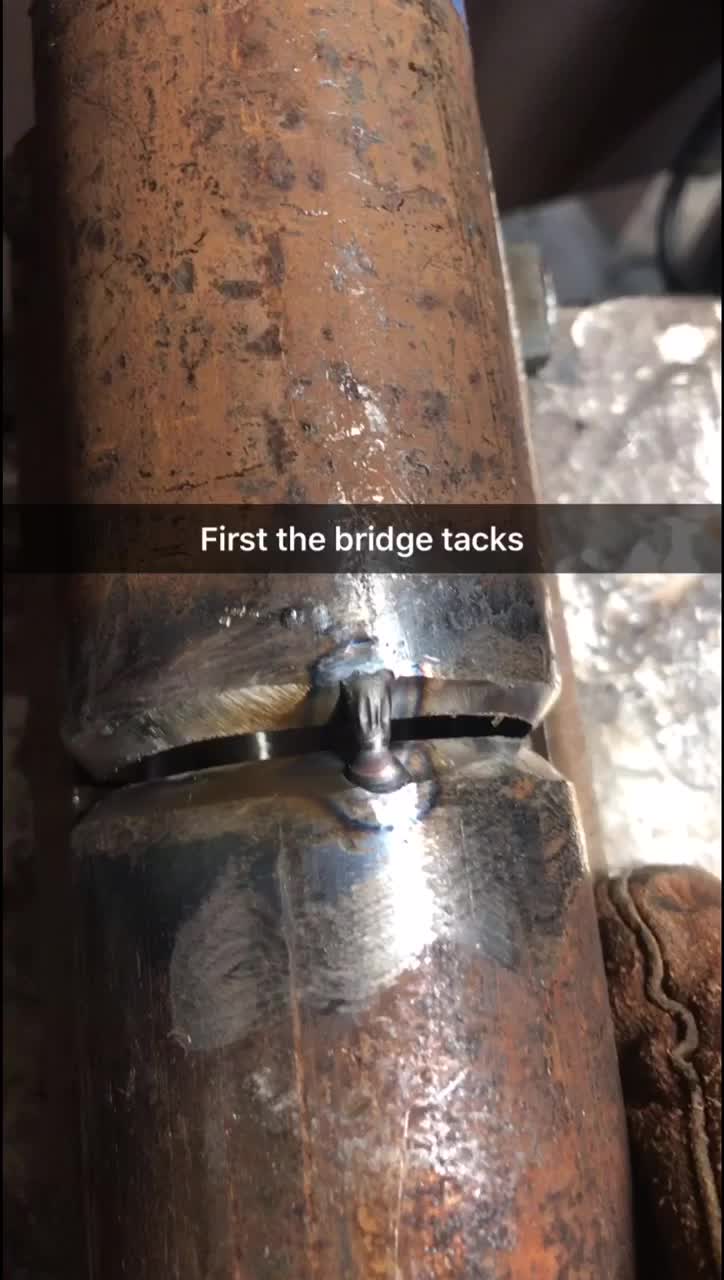

David Cantu

What I am most proud of is that I stuck with welding and my decision to come to Tulsa even though I was more than comfortable back home. The picture was taken in February when TWS Jacksonville was hosting a high school welding competition (I am on the left). The three of us were all from the same school, all were signed up to go to Tulsa, and all planned to live together. However I was the only one of my friends who stayed committed to tulsa and even though I have to live on my own and it is a bit more expensive I am still on track to graduate in February 2019. The video is of my most recent weld which is 2G pipe with a tig root and a 7018 fill and cap. That slag peel is one continuous rod.

Fernando

I am mostly proud of myself for pushing myself to do my best. The biggest challenge I have had in this school are the bevel plate tests. I had never welded before and I feared falling behind. I had to set my job aside and put welding as my priority. I have 3 weeks of doing double shift and hard work pays off. My welds are looking waaay better than when I first started in august.

Ernest

It’s not my weld, it’s just the only photo of welds I had in my phone. The biggest challenge I had so far was with overhead. luckily I have the benefit of being in the afternoon shift, that means two instructors teaching me different ways to skin the same cat. and after 4 days of struggling it finally clicked.

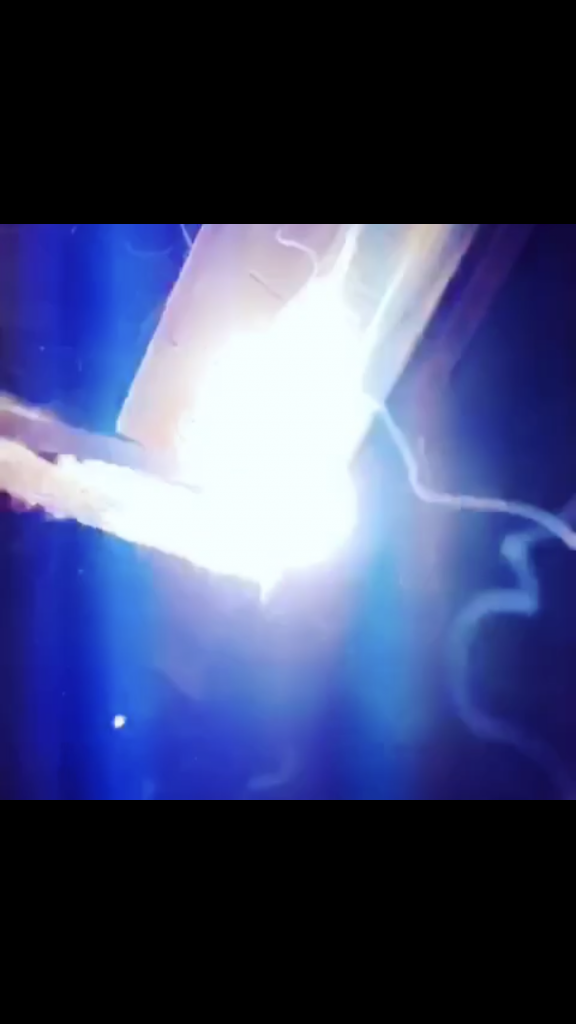

Vincent Loera

I’ve never had the opportunity to learn how to truly weld pipe and to see the end product made me feel accomplished.. it was not an easy road because it had its difficulties but with positive feedback and determination I had it down within 2 weeks.. once I saw what I can produce, I knew automatically that doors were going to open up and they have.. I’m doing things I thought would take me more than years to successfully accomplish with my welds but doing these pipe welds made me realize I was just selling my self short, now I know my true potential and I’m testing it everyday when I go to class at Tulsa school of welding Houston.

Dana Wilkins

Proud Mom sponsoring my son at TULSA WELDING! First welding day! Sam overcame his ADD and a single parent home upbringing without a father. He had attended one year of college and decided that a career in welding would best suit his abilities and mind set. When asked what welding school? Sam didn’t hesitate and chose TULSA!

Britt Fankhauser

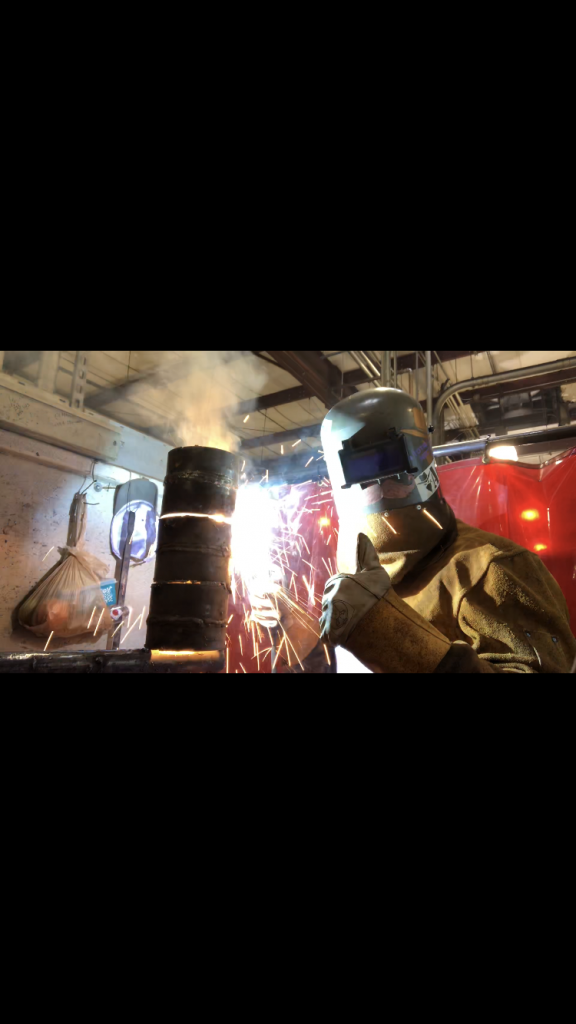

This was for the NFL Hall Of Fame in Ohio. Im most proud of this for the fact there were less then 10 men who worked on this set-up, and i was 1. Did two transmission power poles for them. The challenges i had with this was getting it completed in a day. The cap you see is a 10 bead cap that is 2″x1″. It had well over 100 passes of single 3/32″ wire in the bevel. Then another 75-100 for the cap. Took 18 hours to complete.

Darantay Green

I’m very proud of the success I have found out of my failure period through life choices and decisions I have overcamed a huge obstacle in my life and is now headed into the right direction and with the support of the staff and Tula Welding School itself I’m totally confident that I will become an overachiever and I can say Tulsa Welding School helped redirect my life into a positive motion! So thanks?

DeLynn Muskrat

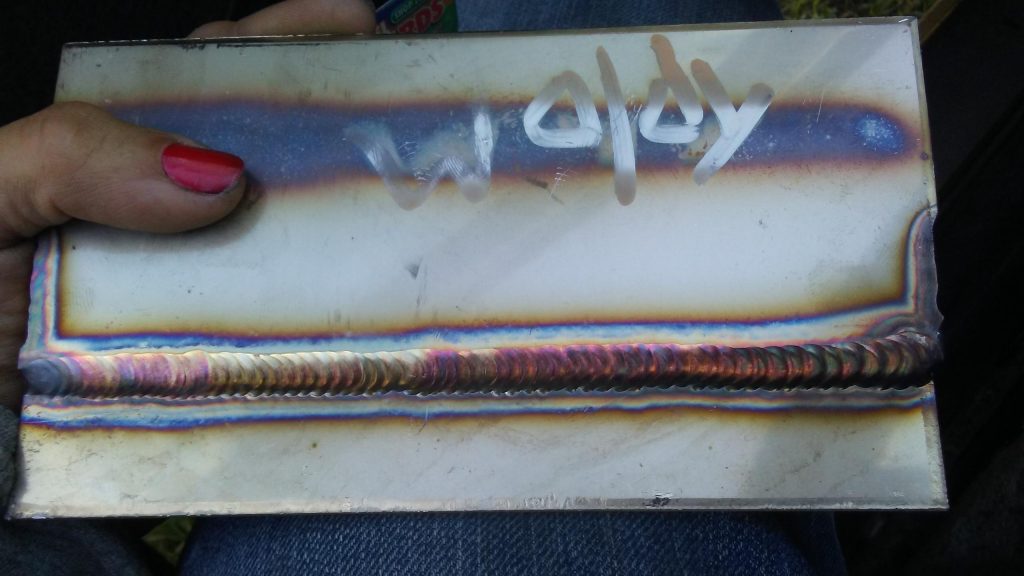

High frequency Tig. lap joint. test piece made a 94 what makes me most proud is that I finally was able to get my heat affected zone even all the way across my plate . and good color. It was challenging to get used to using a foot pedal and how to let up with your foot slowly to keep your puddle hot enough to add filler wire .

Xanthus Bucko

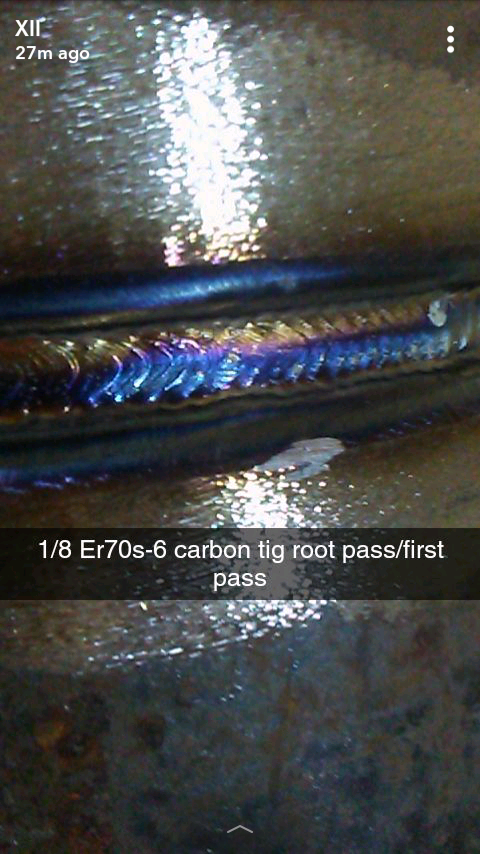

The challenge was keeping the heat effected zone within tollerance without quenching the pipe during the process. To run the right amount of ampere so as to maintain maximum control of the weld puddle allowing the weld to keep within tollerance. Also finding time to weld during the pipe fitting course while maintaining an after school job.

Xanthus Bucko

The challenge was keeping the heat effected zone within tollerance without quenching the pipe during the process. To run the right amount of ampere so as to maintain maximum control of the weld puddle allowing the weld to keep within tollerance. Also finding time to weld during the pipe fitting course while maintaining an after school job.

Lacey Jackson

What I am most proud of is the way my weld looks like a perfect stack of Dimes. Having a wonderful instructor has helped me overcome the frustration from the rod sticking and not getting that straight line in the beginning. With patience and confidence keeping that hand steady I discovered that I’m going to go all the way with this and graduate from Tulsa welding school. Thank you.

Carter Silcox

I am most proud of the skills I have learned overall in welding but especially how my Tig welds looks now. When I first strated Tig i wanted to drop out of school because I thought this just wasn’t for me with the challenge it presented. I kept my head down and continued welding and now here I am in phase ten about to bend out on two separate Tig projects, about to get a job might and Tig welding sheet metal. I am proud of myself for finishing one of the first major achievements of my young life. Excited for what is to come in the future.