TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

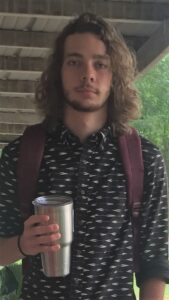

Hunter, 23, from Muskogee, OK, graduated the Professional Welder program at Tulsa Welding School in March 2021.

Thanks for your time, Hunter. What did you do after high school before welding school?

I worked retail. I started working at a grocery store when I got out of high school. I saved up some money and moved to Oklahoma City two years later when I was 20. I continued to work in the grocery line until I came to a point when I realized things weren’t going anywhere. I needed to do something. My sister was living in Tulsa, so we talked about me coming to live with her while I’d go to Tulsa Welding School.

Where did the idea of welding come from?

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

I’d wanted to learn how to weld since I was a kid. When I was 16 or 17, a friend of mine and I were putting a lift kit on my truck. He had to fix something, and I watched him weld it up. That was the first time I’d seen anybody weld and I thought, wow, this is really cool. I’ve always liked working with my hands, whether on cars or bikes. It was just always in the back of my mind that it would be something I would enjoy.

What was it about welding that grabbed your attention?

Just the idea of making things with my hands. I thought it would be satisfying to see the final product. To be able to stand back and say, “Wow…I made that, and it looks really nice!”

So, you didn’t weld at high school?

No. the first time I’d ever touched a welding machine was at Tulsa Welding School.

Did you think of welding as a career? Or was it just something that you were interested in?

It was just something I was interested in, honestly. When I first went to Tulsa Welding School, I was thinking of it as a hobby. Once I started the program, I just really fell in love with it. It took me maybe a week or two to realize this was going to be my career. I’ve never been bored welding once since I started.

Did the instructors help you think about making welding a career?

Very much so. They were very smart, wise people. The knowledge they gave me was something I couldn’t get anywhere else. You can read all the welding books you want, you still wouldn’t know how to weld. It’s just something you’ve got to learn hands on. Having an instructor there to guide you is really beneficial.

What did you enjoy most during your time at Tulsa Welding School?

The amount of time I got to be in my booth welding. When you’re in class, the instructor will do a demo at the start, then you’re off to go weld for the next four or five hours. That was nice. I spent a lot of my time in my booth welding. I didn’t really talk to many people; I was just trying to learn as much as possible.

What shift did you do, and did you have a job while at school?

I did the afternoon shift at school. I wasn’t working, but my sister has two young kids. Part of our deal with me living with her was whenever I wasn’t at school, I would watch the kids. She has a very busy job, so that was kind of my job when I wasn’t at school. But my niece and nephew are great, they are six and four.

Did that give you the time to get extra practice in?

I didn’t get many opportunities towards the beginning, but towards the end I needed to catch up. I was falling behind, so I stayed late quite a bit. The last month and a half or so, I stayed late almost every night.

You just graduated a month ago, where are you working?

Premier Plant Services in Sapulpa, OK. It’s a structural steel fabrication and welding job shop. I got the job through Career Services; Jenna was amazing. She helped me out, got me a weld test. I passed and started the Monday after I graduated. I had the weekend and then started working!

What are you doing for Premier Plant Services?

I am doing flux core, structural, and x-ray welding. We build equipment for the oil field; not machinery, but pretty much anything that you see out in the oil field that is made out of I-beams, like pipe supports. We build it in the shop and then it gets moved out to the oil field.

What’s your schedule?

I work 6 a.m. to 6 p.m. Monday through Friday; sometimes we work the weekends; eight to ten hours Saturdays and up to eight hours Sundays. It can be a lot of work. I worked 68 hours my first week. Anything over 40 hours is overtime.

Wow, that’s a pretty nice paycheck!

Yes, I’m making more money than I have ever made in my entire life. I thought this was going to be a hobby! It’s insane! I’m extremely happy. I’ve also learned so much since I started; I learn new things every day. There is so much to learn in this field, I’m really enjoying it. A twelve-hour shift feels like six or eight hours to me because I’m just busy all the time; that really helps the time go by.

Did you have to move for the job?

No, it’s southwest of Tulsa, so I’m still living with my sister; we just got a house together and it’s been really nice. Everything is going great.

So, not much time to look after the kids anymore?

No, but we are able to get babysitters and all kinds of stuff now!

What’s your career plan from here?

I don’t know how long I’ll be here because this job is dependent on the contracts we get, so last week I only did 40 hours. But we have another project coming in soon that is majority TIG work, so I think I‘m pretty well placed. Having the breadth of knowledge of the different processes I learned at Tulsa has really paid off. I think I’m in a good place because I know how to TIG weld.

Longer term I’d like to weld for maybe the next ten years tops; then I’d like to venture into something else. Whether that’s getting my CWI [Certified Welding Inspector] certification to become a weld inspector, just something higher in this field. There are a lot of opportunities beyond just welding once you get your foot in the door in this field. Welding and metalwork will definitely be my trade for life.

Do you have any ambition to travel, work the pipeline?

Yes, absolutely. I’d love to do pipeline work. It’s just so difficult to get into if you don’t know somebody. I’ve heard that you pretty much have to go through the union to have a chance. Pipelining has been down for about a year though.

You’re young enough to wait for it to come back up.

Yes, for sure, but there are also a lot of overheads to in pipelining that you have to consider. For instance, you need your truck and your welder; if your welder or your truck is broken down, you’re not making money. You have to fix these things. It’s something you definitely have to warm up to, I think.

What do you enjoy most about your new trade?

It’s just a blast. When your hood is down, it’s like there’s nobody else in the world. It’s just you and your weld and the sparks are flying everywhere! You’ve got to make sure your weld is going in there right. It’s just like a whole another feeling, it really is.

What advice do you have for new students, for them to be successful at TWS?

Just stick with it and don’t give up because it only takes one. Once you make one good weld, you’re making good welds on and on and on again. They just keep getting better. If you’re welding, you’ll figure that out.

Did you have days that first phase where you got frustrated?

Oh yeah, absolutely. I have called welders everything but pretty! It is extremely frustrating but once you get it, the satisfaction is overwhelming.

How did you overcome those frustrations?

I just had to finish. It was something I had to do. If I didn’t finish, I still had to pay for the program. If you quit, that’s a lot of money to be paying for not getting anything out of it. It was an investment for me.

If you’re a TWS graduate and would like to share your success and be an inspiration to others, please email [email protected] to be considered for a Graduate Connection interview. Please include details such as your graduation date (month/year), program, and campus name (Tulsa/Jacksonville/Houston).