TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

The best welding shade for the job depends on the type of project you’re working on and the associated risks. Multiple factors can influence which option is the most appropriate. Let’s get into how to choose a welding helmet and take a deeper look at what welding shades are safest.

What Is a Welding Shade?

A welding shade, or welding helmet, is designed to protect your eyes while working. Welding shades shield your eyes from infrared rays, ultraviolet rays and sparks.2 Without the proper shade level on their helmet, welders run the risk of suffering eye injuries like Photokeratitis also called “welder’s flash,”. Photokeratitis is a painful condition resulting from exposure to powerful UV radiation. In addition to intense discomfort, this condition can result in temporary loss of sight.

Welding Shade Ranges for Different Welding Types

Welding shades are marked with numbers that indicate how much light radiation is allowed to pass through. Shade numbers are classified on a sliding scale to help welders understand the extent to which this radiation is blocked from reaching the eyes.

To measure these levels of light filtration, the welding field uses a DIN rating. Welding shades rated with higher DIN numbers are darker and filter more radiation than their counterparts with lower DIN numbers.For example, a shade range of 10 to 13 is advisable for MIG welding. On the other hand, DIN levels of 8 or higher are recommendable for TIG welding, depending on the arc length.

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

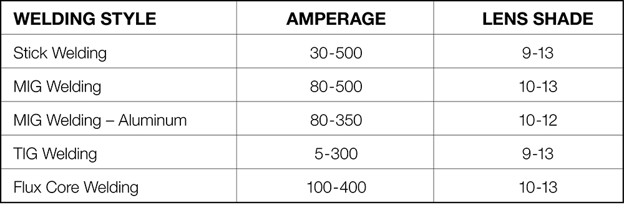

Welding lens shade chat for common welding styles

Check out the welding lens shade chart below from Home Depot to see a detailed breakdown of the different levels.

What is the Safest Welding Shade?

As mentioned before, the safest shade for welding is determined by the type of welding you’re performing.2

Generally speaking, the higher shade numbers ranging from 8 to 13 are designated for welding tasks, while the lower shades that allow more light to pass through are intended for other projects. Grinding is typically associated with DIN 3, while cutting can require a shade number of 5 to 8.

You might assume that the safest shade for welding is the one that blocks the most light, but it’s really about finding the shade level that offers the perfect balance between protection and visibility given the welding process you’re performing.2

To offer some context, a DIN shade level of 3 only lets about 14% of light transmission through. If you go up just one shade level to a DIN 4, just 5% of visible light is allowed through. When bumped up to a shade level 13, an impressive 99.99928% of light is blocked, giving users only 0.00072% of visible light.1

The Importance of Head and Eye Protection in Welding

Each year, numerous eye injuries result from the improper use of welding equipment.2 This alarming information underscores the importance of choosing the right welding helmet and using it properly.

While visors can help protect a welder’s eyes, the rest of the helmet also plays a critical safety role. A helmet can protect your eyes, head, face and neck from a variety of potential hazards.

When selecting a welding helmet, it can be a good idea to consider the protective features of the helmet along with its comfort level. Since you’ll be wearing it for an entire workday, it can be helpful to find a hood that’s lightweight and adjustable while still protecting your face and eyes from potentially harmful sparks and light rays.

To help make it easier for welders to find reliable eye protection, the American National Standards Institute (ANSI) has established guidelines. These criteria set the standard for choosing and servicing eye protection in an attempt to mitigate eye damage and related injuries.

Known as ANSI Z87.1., this industry standard takes several characteristics, such as flame resistance and light leakage, into account.

Make Welding Safety Your Priority

Wherever you are in your welding career, it’s critical to put safety first. And choosing the right welding shade and helmet is just one consideration.

Fortunately, you can find a wealth of welding safety tips in welding school and on the website of the United States Occupational Safety and Health Administration (OSHA).

1 https://welditu.com/welding/tips-mig/what-shade-lens-mig/

2 https://preventblindness.org/wp-content/uploads/2011/12/MK33_OccupEyeInjuries.pdf

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/