TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

Flux-cored arc welding, or FCAW, is a common welding technique that has existed since the 1950s. Arc welding uses an electric arc to generate heat that melts and ultimately binds metal. Since flux-cored welding is taught in welding training programs, here is a brief overview of this welding method.

What is fluxed cored welding?

Flux-cored arc welding is a semi-automatic or automatic arc welding process. This arc welding technique creates an electronic arc through a continuously fed consumable tubular electrode containing a flux (flow) and a constant voltage welding power supply. It is similar to MIG welding, only that the electrode is shielded from air by the flux core. 1 There are two types of flux-cored arc welding, with and without shielding gas.

Flux cored welding advantages and disadvantages

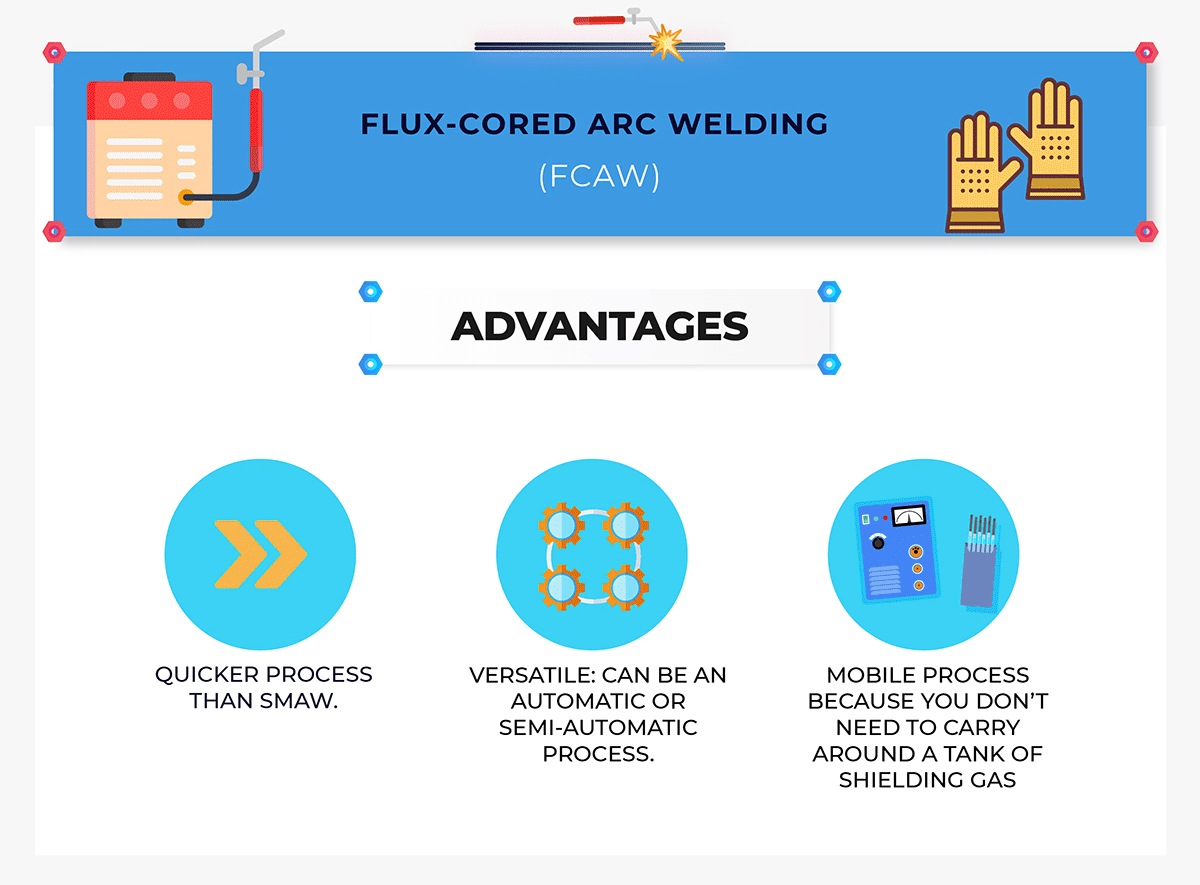

The advantages of flux-cored arc welding include:

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

- Has high efficiency and productivity

- Can be used with many types of metal with different thickness range

- Requires less pre-cleaning than MIG

- Arc is easy to see and use

- No need for gas apparatus

- Can be used outdoors

- Doesn’t require high skill level

However, this welding technique also has some downsides:

- Limited to ferrous metals and nickel-based alloys

- Produces slag that must be removed

- Equipment is more expensive

- Produces more fume than MIG welding 2

Flux cored welding applications and industries

Because of its many advantages, flux-cored arc welding is used in industries that require a high number of welds or involves outdoor welding. It is also used in areas where gas cylinder and gas shielding cannot be readily used, and a useful method for welding material that has some scale, rust, or other contaminants. Flux-cored arc welding is commonly used in the following jobs:

- Ship building

- Construction

- Shop fabrication

- Maintenance

Flux-cored arc welding has been an efficient and reliable welding method for decades. As a professional welder, it is important to know the advantages and disadvantages of each welding method. This knowledge can help determine which techniques to choose for what application.

1 – http://www.gowelding.org/welding/fcaw-flux-cored-arc-welding/

2 – https://www.praxairdirect.com/Industrial-Gas-and-Welding-Information-Center/Welding-Tips-Tricks-and-Information/Flux-Cored-Welding.html

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/