TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

In welding classes, you typically have tools and safety gear you rely on daily. Among them is the welding helmet, a piece of equipment many welders might agree is indispensable.1

Since this safety item must be worn the entire time you are welding to protect your eyes and face, buying a welding helmet is perhaps one of the most important steps you could take on the path to becoming a professional welder.1

In order to truly appreciate the welding helmet, take a look at how these protective pieces have evolved through the years.

A Brief History of Welding Back to Ancient Times

The history of welding can be traced back to the Bronze and Iron Ages because of all the metalwork produced during those eras.2

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

Archeologists found evidence that welding existed in ancient Egypt: gold boxes featuring integrated lap joints that were pressure welded in place dating back 2,000 years. Welding techniques in the Middle Ages involved pounding two pieces of hot metal together until they bonded. Modern welding techniques did not arise until the 19th century.2

Sir Humphry Davy was the first person to fire an electric arc using carbon electrodes and a battery.3

In 1836, acetylene was discovered, and then in 1881 true welding was born when August De Meritens used arc heat to fuse two lead plates. Soon after, a Russian student of Meritens’ came up with a way to use rods to perform carbon arc welding.3

Up until arc welding was officially patented in 1890, it’s hard to say what welders used to protect their eyes and faces.3

1930s: The First Welding Helmet Invented

Before the 1930s, most welders used goggles and face masks to protect their faces. However, this kind of crude safety equipment didn’t do a lot to protect welders from sparks and toxic fumes, and many welders were injured because of the lack of protection.4

The first welding helmet was likely invented during the Industrial Revolution.4 Popular Mechanics published an article in 1937 showing off the new one-piece helmet that was “cut to protect the welder.” The helmet was crafted from vulcanized fiber with a deep-cut structure that wrapped around the sides of the head all the way to behind the ears.5

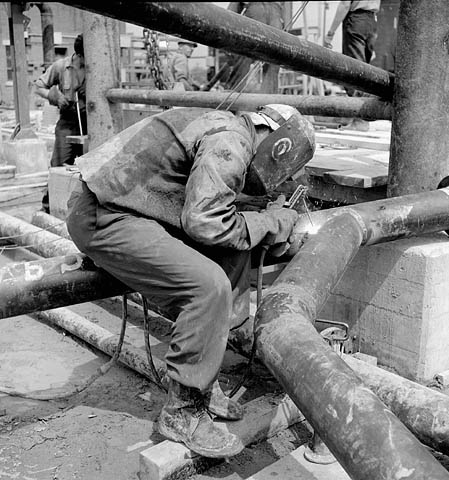

By BiblioArchives / LibraryArchives from Canada – Male welder wearing welding mask joins Y-shaped steam pipe in the Polymer Corporation Limited plant, Sarnia, Ontario (1943)

The earliest welding helmets had a polarized lens for eye protection but likely lacked effective UV radiation protection.4

1980s: Auto-Darkening Filters Introduced

Swedish manufacturer Hornell is recognized as the first to develop welding helmets with LCD electronic shutters. The company introduced the new technology in 1981 under the brand name of Speedglas.4,6

The helmets boasted lens shades with sensors that detected an arc while the welder worked, and the glass automatically darkened to protect the eyes from infrared and UV light.7

In 2004, 3M acquired Hornell and the rights to its auto-darkening filter welding helmets.7

By Ergonomidesign

With these modern helmets, welders could wear the helmet the entire time they worked without the need to raise and lower the helmet or the shade to see clearly when they didn’t need eye protection.1

Some of the primary selling points of these helmets were the increased levels of safety and that they could help speed up welding processes.4

Modern Day Welding Helmets

Workplace safety has continued to evolve throughout the years, and today’s welding helmets are more advanced than ever.1

An industry standard that governs the performance of welding helmets known as ANSI Z87.1 certifies that helmets offer UV and IR protection, are both thermally and electrically insulating and either self-extinguishing or noncombustible in design.8

Helmets can boast a range of features:9

- Fixed or variable shades

- Various shade sizes

- Multiple sensors

- Adjustable sensitivity control, delay controls and lens reaction times

- Lighter-weight construction9

Not to mention, buying welding helmets can be a lot more fun these days. You can select a helmet that matches your personality or interests thanks to varied color options and graphic imagery applied to the helmet exterior.1

Petty Officer 3rd Class Joshua Nistas / Public domain

How to Choose Your Welding Helmet

Wondering how to choose a welding helmet? Selecting the right one can depend on the type of welding you do, your personal preferences and even how much personality you want to show off. One thing is certain, though: compared to the welders who came before you, you’ll likely have plenty of options.1

1https://www.ehstoday.com/ppe/eye-face-head/article/21919193/eye-and-face-protection-tips-for-choosing-the-right-autodarkening-welding-helmet

2https://www.fairlawntool.com/blog/history-of-welding/

3https://www.millerwelds.com/resources/article-library/the-history-of-welding

4http://www.weldinghelmetgenius.com/history-of-welding-helmets/

5https://books.google.com/books?id=79oDAAAAMBAJ&pg=PA217&dq=Popular+Science+1933+plane+%22Popular+Mechanics%22&hl=en&ei=RasMTuyGFYifsQLC3sGzCg&sa=X&oi=book_result&ct=result&resnum=2&ved=0CC0Q6AEwATgK#v=onepage&q&f=true

6http://www.3m.com/intl/eu/ohes/europe/speedglas/female_graphic/microsite/eu/speedglas-story.html

7https://news.3m.com/press-release/company/3m-acquire-hornell-international-expands-safety-products-line

8https://ohsonline.com/Articles/2014/11/04/Ensuring-Full-Protection.aspx

9https://www.millerwelds.com/resources/article-library/selecting-the-right-welding-helmet-for-you

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/