TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

When it comes to a career in welding, all the different types methods and technologies can seem overwhelming. From plasma arc welding to laser welding, each of the options available to professionals offers different benefits for various jobs and materials. As Modern Machine Shop points out, each type of welding has specific advantages depending on the welder’s goal, and selecting the right equipment and methods can save time and money in the production of the product and in avoiding potential damages or poorly finished materials. This is an overview of the main techniques used in the industry intended for those who are considering enrolling in a welding training program.

Considerations to make when selecting the right type of welding

When determining the best type of welding for a particular project, it is important to examine a number of different factors. These considerations should include:

- The type of material being welded (including how reflective the surface is).

- The thickness of the material.

- The amount of time at the welder’s disposal for the project (certain types of welding will be able to progress much faster than others).

- The amount of electrical current available to power the machines and the type of welding power source needed.

Common types of welding

Arc Welding

Arc welding is one of the more common forms of welding. According to Go Welding, this type of welding generally offers a low overall cost for the project, making it appealing to many. This technique involves an electric current being created between the welding device and the material that is to be welded. Basic arc welding has been used for more than 200 years.

Gas Metal Arc Welding

GMAW, also referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is commonly used to help save time, as it is easily automated and very versatile. It is mostly used in the automotive industry. Invented in the 1940, this technique makes use of a welding gun striking an electric arc while also distributing a shielding gas. While GMAW was initially developed for aluminum, it was soon applied to steels as well.

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

Shielded Metal Arc Welding

SMAW or “stick welding” is likely the most common used technique today. In this manual arc welding process, a consumable electrode coated in flux generates is used. An electric current derived from a welding power supply forms an electric arc between the electrode and the material to be joined. While the flux coating disintegrates, its vapors serve as a shielding gas and provide a layer of slag. SMAW is popular in the construction of steel structures and industrial fabrication due to its versatility and simplicity.

Flux-cored Arc Welding

Flux-cored arc welding (FCAW or FCA) requires a continuously fed consumable tubular electrode containing a flux and a constant-voltage or constant-current power supply. The flux typically also produces shielding gas and liquid slag. This technique originated in the 1950s and is widely used in construction due to its high welding speed and portability.

Gas Tungsten Arc Welding

GTAW or (also called tungsten inert gas or TIG) is a technique that uses a non-consumable tungsten electrode to weld the material. In this process, the weld area is protected by a shielding gas and a filler material is typically used. This welding technique is mainly used for thin sections of stainless steel, aluminum, magnesium, and copper alloys. However, this method is comparatively complicated and slow.

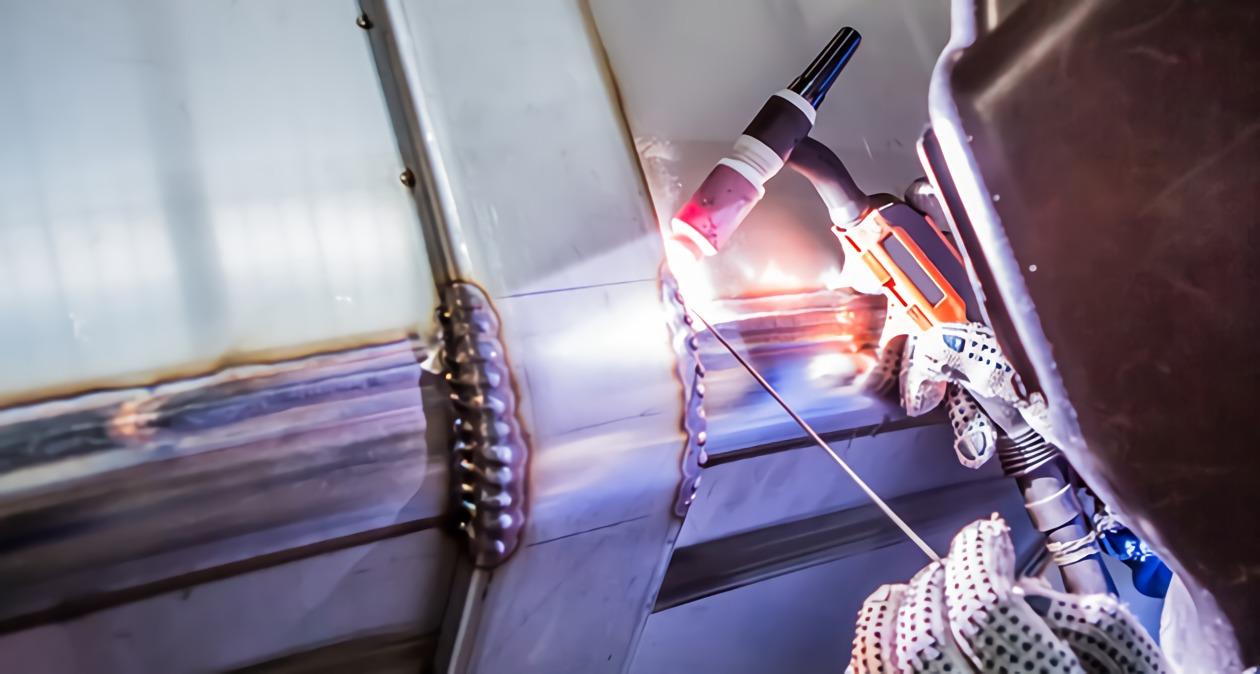

Plasma arc welding

Plasma arc welding (PAW) is a similar to GTAW in that it also involves an electric arc being formed between an electrode and the materials being welded. The difference between the two is that the plasma arc can be separated from the shielding gas by positioning the electrode within the torch. This can generate extremely high temperatures, which can result in deep welds. PAW also enables great accuracy. It is used widely in the aviation industry.

Submerged arc welding

SAW requires a continuously fed consumable solid or tubular electrode. The molten weld and the arc are protected from sparks and splatter by being submerged under granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride and other components. Compared to shielded metal arc welding, submerged arc welding can increase productivity by 4 to 10 times according to Weld My World. This process can be semi-automatic or automatic, but is limited to horizontal welds. It is most often seen for high speed sheet welding.

Other welding techniques

While arc welding methods are the most commonly used, there are a few other types of welding that professionals use to generate particular types of bonds. Laser welding is one type of welding that has been growing in popularity because of its ease of automation and its ability to be used on a number of different materials at different thicknesses. Other types of more specific welding techniques include ultrasonic vibrations or explosion welding.

Those preparing to enter the welding industry should carefully review and consider the benefits of the different types of welding before they sit down to complete a job. Selecting the best format can help save time, money, and produce a far superior final product.

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/