Trade School Programs at TWS

Gain valuable skills for a sustainable career sooner than you think.

Select A Location:

Select A Location:

Welding

Professional Welding Training

Duration:

7 months

Welding

Associate of Occupational Studies in Welding Technology

Duration:

14 months

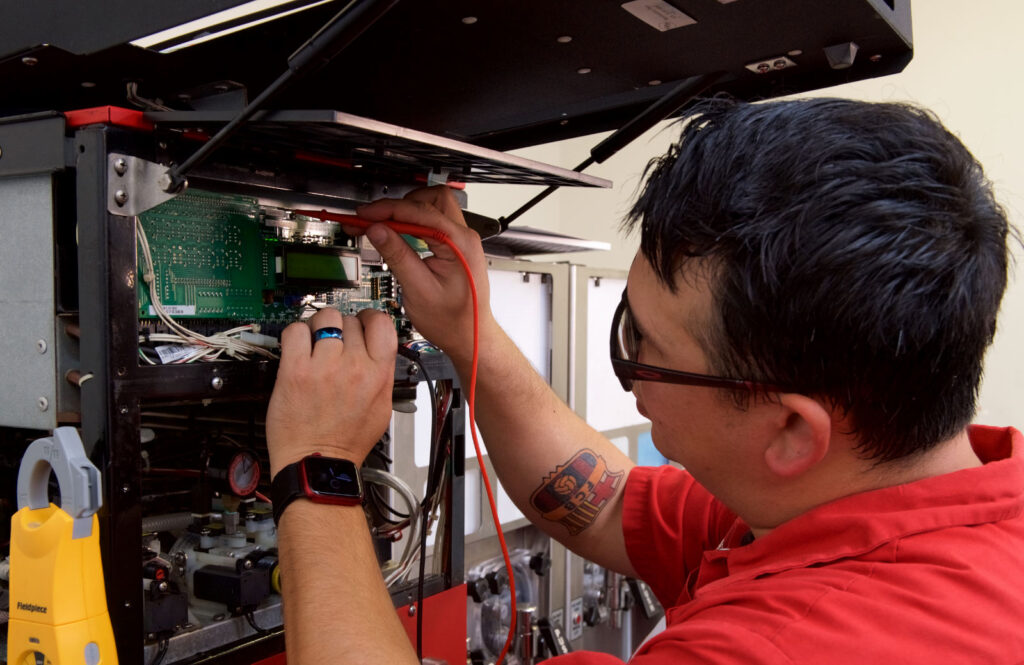

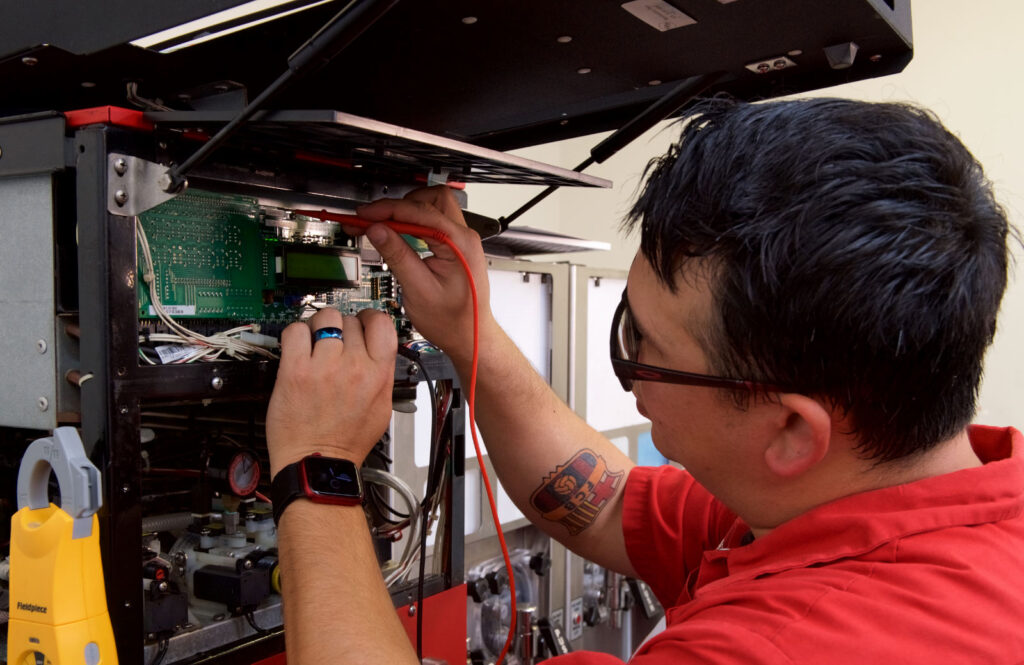

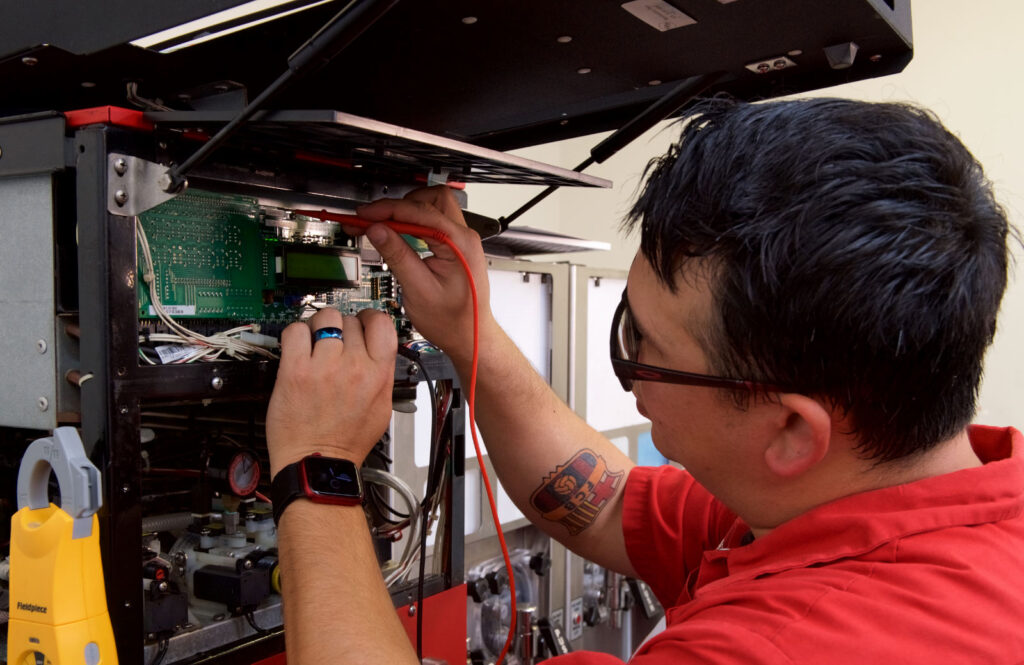

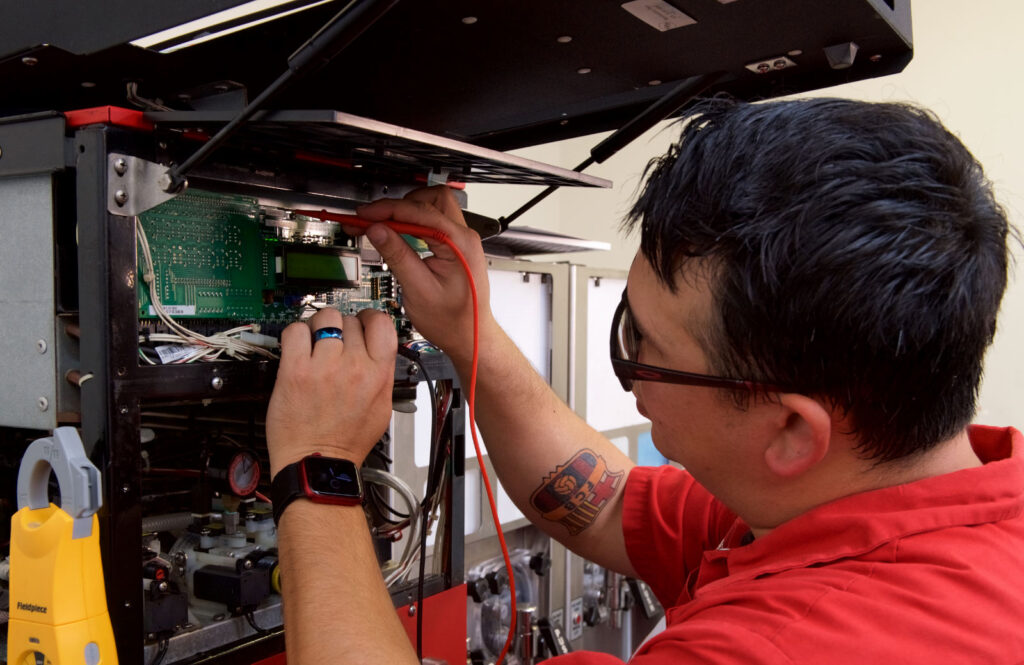

HVAC / Refrigeration

Refrigeration Technologies

Duration:

7 months

HVAC / Refrigeration

Electro-Mechanical Technologies

Duration:

9 months

Electrical

Electrical Applications

Duration:

7 months

Welding

Professional Welding Training

Duration:

7 months

Welding

Welding and Pipefitting Training Program

Duration:

9.5 months

Welding

Associate of Occupational Studies in Welding Technology

Duration:

14 months

HVAC / Refrigeration

Refrigeration Technologies

Duration:

7 months

HVAC / Refrigeration

Electro-Mechanical Technologies

Duration:

9 months

Electrical

Electrical Applications

Duration:

7 months

Electrical

Electrical Lineworker Training

Duration:

3.5 months

Welding

Professional Welding Training

Duration:

7 months

Welding

Welding and Pipefitting Training Program

Duration:

9.5 months

HVAC / Refrigeration

Refrigeration Technologies

Duration:

7 months

HVAC / Refrigeration

Electro-Mechanical Technologies

Duration:

9 months

Electrical

Electrical Applications

Duration:

7 months

Industrial Maintenance

Advanced Industrial Maintenance Technology

Duration:

7 months

Welding

Associate in Applied Science in Welding Inspection and Quality Management

Duration:

14 months

Welding

Professional Welding Training

Duration:

7 months

HVAC / Refrigeration

Refrigeration Technologies

Duration:

7 months

Electrical

Electrical Technologies

Duration:

7 months

Electrical

Electrical Lineworker Training

Duration:

3.5 months

Industrial Maintenance

Advanced Industrial Maintenance Technology

Duration:

7 months

New: Industrial Maintenance

Learn About Our New Advanced Industrial Maintenance Program

Tulsa Welding School is proud to announce our newest program offering available at our Houston & Dallas Metro Campuses – Advanced Industrial Maintenance Technology! Learn the skills you need to take on the industries of manufacturing, distribution, energy production and facility maintenance in as few as 7 months.

ALL New Welding Students Get an Oculus Quest 2 loaded with OcuWeld Training Software!

TWS is excited to launch OcuWeld utilizing Virtual Reality (VR) to enhance your welding training. OcuWeld is a new and innovative Virtual Reality (VR) welding simulator designed by expert welding instructors for our welding students.

You can access OcuWeld anytime, anywhere – with or without WIFI. It enables you to practice your welding skills as part of our program here at TWS and the Oculus Quest 2 is yours to keep!

Select the Program That is Right For You

Our Admissions Representatives are standing by to talk to you about your life situation, personal interests and career goals. We’ll work with you to figure out which TWS training program is right for you. Click below to contact us today!

Experiences & Opportunities

Resources for TWS Students

Virtual Tour

Take a virtual tour of our campuses! Explore the classrooms, labs and shop floor with our unique interactive experience.

Employer Relationships

TWS has relationships with major employers across the United States. Our dedicated Career Services team will be there to support you every step of the way after graduation.

The Right Tools for the Job

When you begin your education at TWS, we provide you with an extensive gear package. You get the high quality professional tools you need to succeed. Ask your Admissions Representative for more information about the gear package for your program.

Scholarship Opportunities

Learn more about what scholarship opportunities are available and how you might qualify for one. Start the process of applying for a scholarship today!

Are YOU ready to change your life?

Listen to these TWS graduates who changed theirs.

We all come from different walks of life, and different circumstances, but it’s the hard work we do and the blood sweat and tears put in to make us who we are today.

Tulsa Welding School gave these graduates the structure, confidence, and guidance they needed to make a difference in their lives. It only takes one decision to start the journey on a path towards a better career. A better Life.

Hear the stories of these TWS graduates and how they changed their lives:

Jonathan Garza

Coming from a place of darkness and addiction, Jonathan made the change he needed to get his life back on track for his family, career, and his stability. Professional Welding Graduate from our Houston campus - Hear his story on how TWS changed his life.

David Mclean

With so many options in front of him and no clear path ahead, David chose to invest in his life and make the decision to enroll at a trade school. TWS gave him the opportunities to be the best version of himself he could be. Professional Welding Graduate from our Jacksonville campus - Hear his story on how TWS changed his life

Cody Hudgens

Not basing his chances on luck, Cody took the opportunity of becoming a welder in his own hands after serving in the United States Marine Corps. TWS gave him the knowledge and skills he needed to take his passion to the next level. Professional Welding Graduate from our Tulsa campus - Hear his story on how TWS changed his life

Ready to Move Forward?

All it takes to move forward is making that first step. Whether you need more information, schedule a tour or want to speak to someone, we’re with you every step of the way.