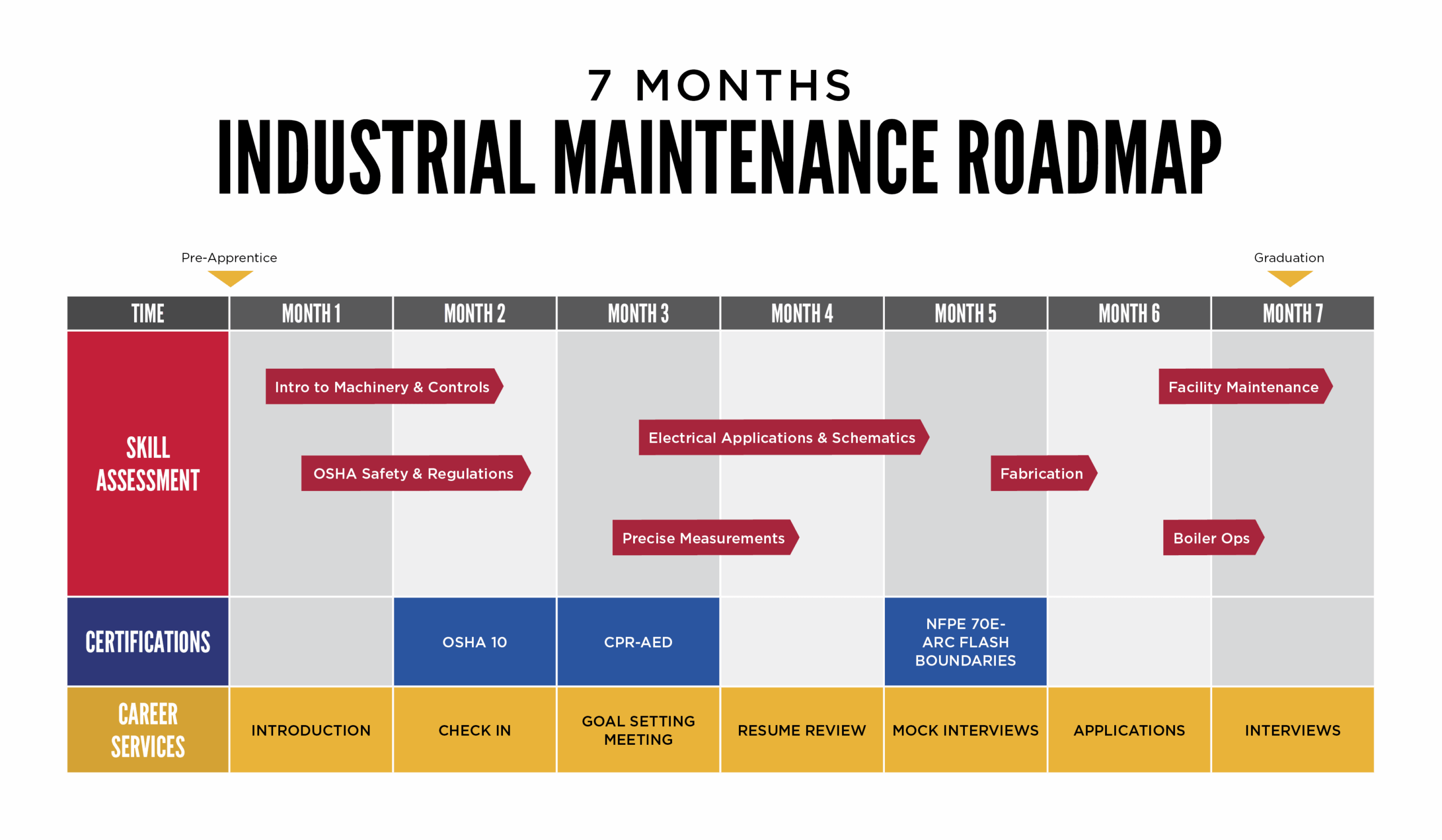

Upcoming Start Dates

Feb. 12, 2026 & Apr. 9, 2026

Duration: 7 months

7 months of hands-on training and real-world skills.

Campus Availability

THE BEST TIME TO REPAIR A MACHINE IS BEFORE IT BREAKS

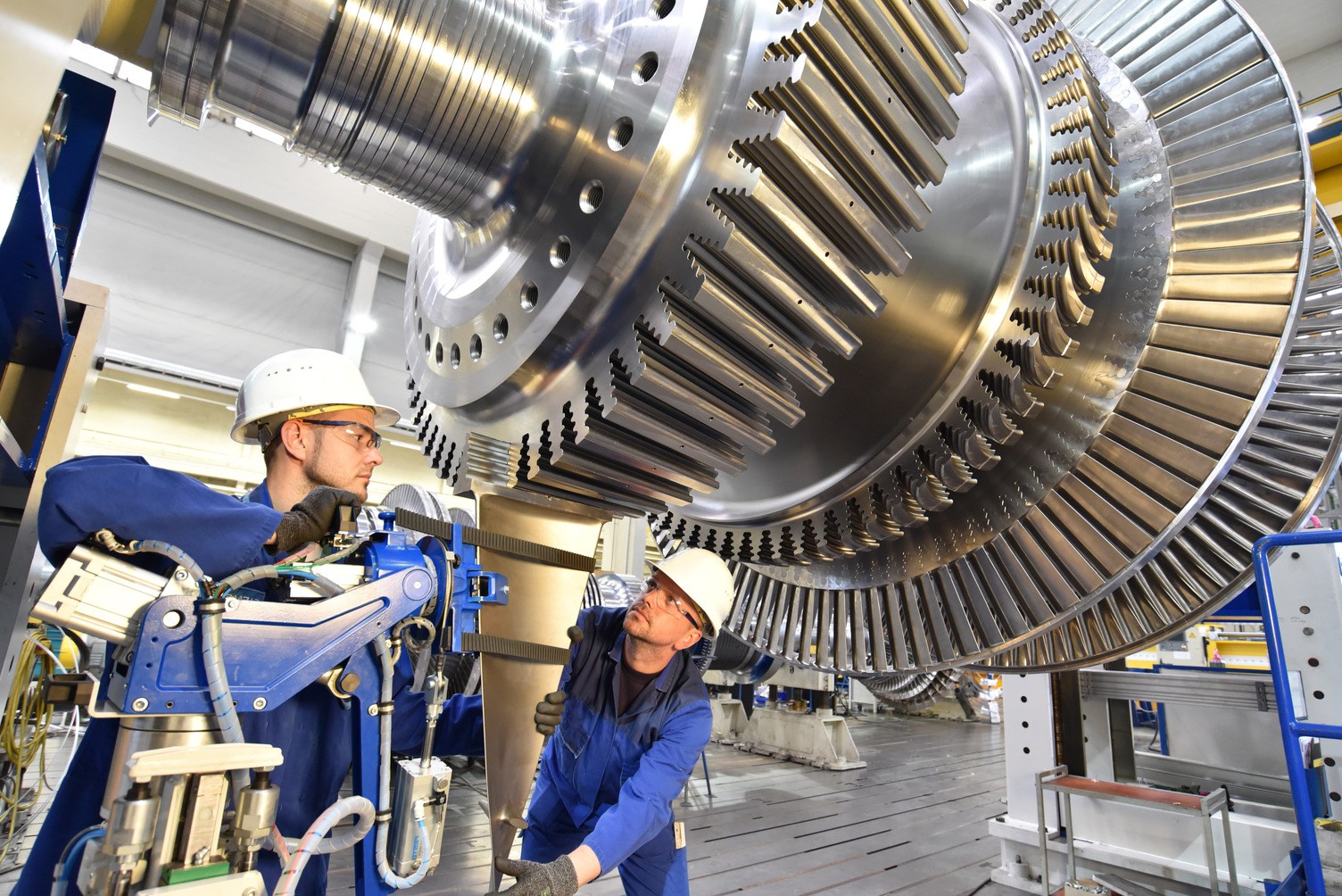

The Advanced Industrial Maintenance Technology program at Tulsa Welding School (TWS) combines hands-on training and expert instruction to help you build real-world skills. This program prepares students to maintain and repair the complex systems used in manufacturing, distribution, energy production, and facility operations.

You’ll train in a practical, lab-based environment where you’ll learn to:

- Diagnose and troubleshoot mechanical and electrical systems

- Work with programmable logic controllers (PLCs) and automated equipment

- Maintain industrial machinery and equipment to prevent breakdowns

- Apply safety protocols like Lockout/Tagout (LOTO) and arc flash boundaries

- Use tools and test equipment found in real industrial settings

- Follow technical manuals and schematics to complete service tasks

What is Industrial Maintenance?

The Advanced Industrial Maintenance Technology program at Tulsa Welding School available at the Dallas Metro and Houston, TX campuses is a hands-on, 7-month training program designed to prepare students for careers in equipment maintenance, industrial automation, and facility operations. The program combines mechanical, electrical, and automation training—including Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) instruction—used in today’s smart factories and industrial systems.

Industrial maintenance technicians keep complex systems running safely and efficiently. They support equipment-heavy industries like manufacturing, energy, and logistics by spotting mechanical and electrical issues early. Through inspections, basic troubleshooting, and routine servicing, these technicians help reduce downtime and improve overall system reliability.

What you will learn

The Advanced Industrial Maintenance program at TWS teaches you how to use electrical and mechanical tools to maintain, repair, and replace industrial equipment. You’ll gain hands-on experience in areas such as:

- Programmable Logic Controller (PLC) Fundamentals and Programming

- Junction Boxes & Transformers

- Belted & Motor Drives

- Hydraulic & Pneumatic Machinery

- Boiler & Steam Operations

- Safety Compliance & OHSA 10 Standards

What does the industrial maintenance career path look like?

Starting Your Career Journey – 0-3 years

As a graduate of the Industrial Maintenance Technician Training program, you’ll begin in hands-on technical roles that develop your core skills in repair, maintenance, and system support. These positions often include:

- Equipment Maintenance Technician: Perform routine checks, service equipment, and assist with minor repairs.

- Mechanical Systems Installer: Set up machinery and mechanical components in industrial or commercial settings.

- Operations Support Technician: Assist maintenance teams with diagnostics, part replacement, and safety procedures.

Growing Your Expertise – 3-6 years

As your knowledge and confidence grow, you may take on roles with broader responsibilities, specialized equipment, or oversight of facility systems:

- Power Generation Specialist: Monitor and maintain machinery used in power production environments.

- Facilities Operations Coordinator: Oversee multiple building systems, schedule maintenance, and handle equipment performance issues.

- Senior Equipment Mechanic: Troubleshoot complex problems, mentor junior technicians, and handle system rebuilds.

Advancing Your Career – 6-10 years

With long-term experience and training, you may step into roles that involve supervision, system integration, or specialized diagnostics:

- Maintenance Team Supervisor: Lead technicians, manage workflow, and coordinate with engineering and safety teams.

- Automation and Control Systems Technician: Work with PLCs, HMIs, and automated systems to support smart factory operations.

- Reliability Engineer Assistant: Support engineers in analyzing system performance and recommending long-term maintenance strategies.

Employment is Expected to Grow for Industrial Maintenance in the US by 43,500 Jobs by 2033!i

Where Can a Career in Industrial Maintenance Take You?

Industrial maintenance careers are essential to keeping operations running and equipment functioning. Whether you’re maintaining robotic arms on a production line or troubleshooting electrical control systems, your work helps prevent breakdowns and keeps things moving efficiently.

These roles span multiple industries, including manufacturing, logistics, and energy. You might become a maintenance technician, automation specialist, or systems mechanic. Each role offers hands-on challenges, technical growth, and the chance to work with complex machinery. Explore the paths below to find one that fits your skills and interests.

Industrial Maintenance Technicians are responsible for inspecting, repairing, and maintaining equipment used in manufacturing, processing, or power generation. They troubleshoot mechanical, hydraulic, pneumatic, and electrical systems to minimize downtime and ensure smooth operations.

Maintenance Mechanics specialize in keeping industrial machinery and equipment in working order. Their duties include replacing worn parts, performing routine inspections, and responding to system breakdowns to maintain production efficiency.

Millwrights are skilled tradespeople who assemble, install, align, and dismantle heavy industrial machinery. They use tools like precision measuring instruments, welding equipment, and rigging systems to relocate or rebuild complex mechanical systems.

PLC (Programmable Logic Controller) Technicians program, troubleshoot, and repair automated control systems. They ensure manufacturing and processing equipment runs according to set logic and work closely with engineers to improve system functionality.

Automation Technicians maintain and optimize automated machinery and control systems used in production environments. They install sensors, maintain robots, calibrate equipment, and work with HMIs and SCADA systems to keep automated systems running efficiently.

SCADA (Supervisory Control and Data Acquisition) Technicians monitor and control industrial systems through networked software interfaces. They install, configure, and maintain SCADA systems to manage processes across utilities, energy, and large-scale manufacturing operations.

CNC (Computer Numerical Control) Maintenance Technicians are responsible for maintaining and repairing CNC machinery used in precision manufacturing. They troubleshoot mechanical and electronic malfunctions and ensure accurate calibration of automated cutting, milling, and turning equipment.

Boiler Operators manage the safe operation of boilers and steam systems in industrial or commercial facilities. Their work includes monitoring pressure gauges, performing regular maintenance, and troubleshooting issues related to heating and steam distribution systems.

Facilities Engineers oversee the maintenance and functionality of buildings and mechanical systems such as HVAC, power supply, and plumbing. They manage building upgrades, energy efficiency improvements, and long-term maintenance plans.

Maintenance Planners schedule and coordinate preventive and corrective maintenance tasks. They create maintenance workflows, manage inventory of parts and tools, and help reduce downtime by keeping work orders organized and timely.

Utility Technicians install, repair, and maintain systems that deliver utilities such as water, electricity, gas, and steam. They often work for municipalities, utility providers, or large facilities with their own power and plumbing infrastructure.

These technicians inspect and service mechanical and electrical equipment within power generation plants. They work on turbines, boilers, generators, and switchgear to ensure energy systems operate safely and reliably.

Lift Truck Mechanics specialize in the repair and maintenance of forklifts and other industrial material-handling equipment. Their work includes engine diagnostics, hydraulic system repairs, and brake system servicing.

Conveyor Maintenance Technicians maintain and repair conveyor belt systems used in warehouses, manufacturing, and logistics facilities. They ensure proper alignment, tension, and motor function to keep automated systems operating without interruption.

Assembly Technicians build and assemble machinery or equipment using schematics, blueprints, or verbal instructions. They may work in light or heavy industrial settings, ensuring each component meets exact specifications.

Machine Operators run industrial equipment for manufacturing or processing. They monitor production processes, inspect finished parts, make basic adjustments to machinery, and ensure quality standards are met.

Maintenance Supervisors lead teams of technicians and mechanics in performing repairs, installations, and preventive maintenance. They oversee work orders, enforce safety procedures, and manage departmental goals to keep facilities running efficiently.

Maintains, troubleshoots, and repairs electrical systems, machinery, and equipment to ensure safe and efficient operations in industrial or commercial settings.

Installs, calibrates, and maintains instruments and control systems that monitor and regulate industrial processes, ensuring accuracy and efficiency.

Provides on-site installation, maintenance, and repair services for equipment or systems at customer locations, often requiring travel and direct client interaction.

Serves as a subject matter expert on specific equipment, offering technical support, training, and recommendations for operation, maintenance, and improvements.

Manages relationships with suppliers and service providers, ensuring quality, cost-effectiveness, and timely delivery of goods and services.

Maintains and troubleshoots systems related to power generation, distribution, and energy efficiency, including renewable energy technologies.

Operates and monitors equipment that treats and purifies water or wastewater, ensuring compliance with safety and environmental regulations.

Conducts routine inspections, servicing, and adjustments on machinery and systems to prevent breakdowns and extend equipment lifespan.

Flexible Class Schedules

Morning and Evening Classes Available

At Tulsa Welding School, we understand that life doesn’t pause when you start training. Whether you’re graduating from high school, changing careers, or transitioning from military service, our flexible class schedules are designed to fit your life.

The Industrial Maintenance Technician Training program offers both morning and evening class options, depending on the campus. This gives you the opportunity to work part-time, manage personal commitments, or balance other responsibilities while completing your training.

Our admissions team can help you find a schedule that supports your career goals and keeps you on track to graduate in just 7 months. Contact us to learn more about upcoming start dates at our Houston and Dallas Metro campuses.

Frequently Asked Questions (FAQ)

The AIMT program prepares students with foundational knowledge and hands-on experience aligned with industry certifications, including:

- OSHA 10 Certification

- CPR-AED

- NFPE 70e – Arc Flash Boundaries

- Lockout/Tagout (LOTO) training

- Basic PLC programming and HMI operations

- CMMS software exposure

Certified Maintenance & Reliability Technician (CMRT)

- Offered by: Society for Maintenance & Reliability Professionals (SMRP)

- Recognized across industries; validates knowledge in preventive and corrective maintenance, troubleshooting, and predictive maintenance.

Certified Maintenance & Reliability Professional (CMRP)

- Offered by: Society for Maintenance & Reliability Professionals (SMRP)

- Unlike the CMRT, which is designed for technicians, the CMRP is a higher-level certification targeted at professionals who manage or lead maintenance and reliability efforts within organizations. It’s aimed at supervisors, managers, engineers, and consultants responsible for maintenance strategy, reliability engineering, and asset management.

EPA Section 608 Certification

- Required by federal law to service systems containing refrigerants

- Useful for AIMT grads who work with chillers, HVAC, or boiler systems in industrial settings.

NCCER Industrial Maintenance Mechanic Certification

- Offered by: National Center for Construction Education and Research

- Covers rigging, lubrication, power transmission systems, pumps, and alignment—ideal for hands-on industrial maintenance roles.

Siemens S7 PLC Certification (Step 7 Programming)

- Validates your ability to work with Siemens automation platforms, common in global operations.

ISA Certified Control Systems Technician (CCST)

- Offered by: International Society of Automation (ISA)

- Best suited for those advancing into instrumentation, automation, or SCADA roles.

Your ideal certification(s) will depend on your career path, such as:

- Controls/Automation → CCST, Rockwell/Siemens PLC training

- General Industrial Maintenance → CMRT, NCCER, LOTO

- Facilities Maintenance (HVAC/Boilers) → EPA 608, Boiler Operator License

- Manufacturing/Production Support → CPT, Forklift, OSHA 10

These credentials and skills can support future certification paths through organizations like:

- The Society for Maintenance & Reliability Professionals (SMRP)

- National Institute for Certification in Engineering Technologies (NICET)

- International Society of Automation (ISA)

Graduates of the AIMT program are qualified for entry-level to mid-level roles in industrial maintenance and automation. Job titles may include:

- Industrial Maintenance Technician

- Electro-Mechanical Technician

- PLC Technician

- Automation Technician

- SCADA Technician

- Millwright

- CNC Maintenance Technician

- Boiler Operator

- Maintenance Mechanic

- Power Plant Maintenance Technician

- Utility Technician

- Facilities Engineer

- Lift Truck Mechanic

- Maintenance Planner

- Conveyor Maintenance Technician

- Assembly Technician

- Machine Operator

- Maintenance Supervisor (with experience)

Advanced Industrial Maintenance Technology graduates can work across multiple industries that rely on automated equipment, heavy machinery, and facilities systems, such as:

- Manufacturing (aerospace, food & beverage, automotive, consumer goods)

- Power generation (nuclear, solar, gas, and coal plants)

- Logistics and warehousing (distribution centers and fulfillment operations)

- Utilities (water treatment, gas, and electrical plants)

- Commercial building operations (museums, hospitals, universities)

- Oil and gas

- Military and government facilities

These industries often seek technicians skilled in automation, mechanical systems, and electrical troubleshooting, and some of the example types of employers can include the following:

- Large manufacturers and production plants

- Public utilities and energy providers

- Commercial and institutional facilities (e.g., hospitals, schools, museums)

- Oil and gas refineries

- Third-party maintenance and field service providers

- Data centers and high-tech facilities

- Government and military installations

- Graduates may also work in union or non-union shops, depending on the region and employer.

Students will train using industry-standard tools, systems, and technologies, including:

- PLCs (Programmable Logic Controllers) from major brands like Allen-Bradley

- VFDs (Variable Frequency Drives)

- HMI (Human-Machine Interface) panels

- Multimeters, clamp meters, and oscilloscopes

- Electric motors, gearboxes, belts, and drive systems

- Pneumatic and hydraulic valves, pumps, and actuators

- CMMS software systems for digital maintenance tracking

- Industrial control panels and wiring terminals

- Boilers, RTUs, and HVAC systems

One of the core components of the AIMT program is hands-on PLC training. Students learn:

- PLC programming fundamentals

- Troubleshooting automation logic and sensor signals

- Configuring HMI screens for industrial control

- Working with motor drives and control loops

- Simulating automated systems to diagnose faults

This training prepares graduates for the growing demand in automated systems maintenance and industrial controls troubleshooting.

Technicians typically work in environments that include:

- Factory floors and production lines

- Power plants and industrial facilities

- Outdoor utility stations and mechanical rooms

- Climate-controlled mechanical shops or warehouses

Work may involve rotating shifts, overtime, or on-call hours depending on the industry. Safety training, PPE use, and adherence to OSHA standards are a regular part of the job.

The AIMT program is ideal for individuals who:

- Enjoy working with their hands and solving technical problems

- Are interested in mechanical systems, electrical circuits, and automation

- Are looking to enter the skilled trades with high earning potential***

- Want to work in manufacturing, utilities, energy, or facility operations

- Prefer practical, hands-on learning over traditional lecture formats

No prior experience is required; just a willingness to learn and a strong work ethic. After as few as 7 months, you’ll have the skills needed today’s employers are looking for including:

- Mechanical Aptitude: Ability to understand, troubleshoot, and repair mechanical systems such as motors, pumps, conveyors, and hydraulic or pneumatic equipment.

- Electrical Knowledge: Basic to intermediate understanding of electrical circuits, wiring, control panels, and the ability to read electrical schematics and blueprints.

- PLC & Automation Skills: Familiarity with Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and automated control systems used in modern industrial equipment.

- Troubleshooting Ability: Strong problem-solving skills to diagnose equipment failures quickly and accurately, minimizing downtime.

- Use of Tools and Instruments: Proficiency with hand tools, power tools, electrical testers, meters, and precision measuring devices.

- Safety Awareness: Knowledge of workplace safety practices, including OSHA standards, Lockout/Tagout procedures, and proper handling of hazardous materials.

- Reading Technical Documentation: Ability to interpret manuals, technical drawings, wiring diagrams, and maintenance logs.

- Physical Dexterity and Stamina: Comfort working in physically demanding environments, often involving standing, bending, lifting, and working in confined spaces.

- Attention to Detail: Precision in performing repairs and preventive maintenance to ensure equipment reliability and safety.

- Communication Skills: Ability to document work clearly and communicate effectively with team members, supervisors, and engineers.

- Adaptability and Continuous Learning: Willingness to learn new technologies and keep up with advances in industrial automation and maintenance practices.

Class Start Dates and Scheduling

Campus Start Dates

Location

Date

Houston, TX

Feb. 12, 2026 & Apr. 9, 2026

Dallas, TX

Feb. 12, 2026 & Apr. 9, 2026

Class Schedule Options

Students may choose from any of the following flexible options

HYBRID INSTRUCTION

At TWS, we know you’re here to build real-world skills, not spend endless hours in a classroom. That’s why we offer a flexible online hybrid model, allowing you to complete the theoretical parts of your program online, as long as it’s done by the deadline. When you’re on campus, your time is spent where it counts: hands-on in the lab with tools, equipment, and expert instructors.

This approach gives you the freedom to balance school with other responsibilities, while still getting the hands-on training you need for a successful career in the skilled trades.

Experiences & Opportunities

Resources for TWS Students

Virtual Tour

Take a virtual tour of our campuses! Explore the classrooms, labs and shop floor with our unique interactive experience.

Employer Relationships

TWS has relationships with major employers across the United States. Our dedicated Career Services team will be there to support you every step of the way after graduation.

The Right Tools for the Job

When you begin your education at TWS, we provide you with an extensive gear package. You get the high quality professional tools you need to succeed. Ask your Admissions Representative for more information about the gear package for your program.

Scholarship Opportunities

Learn more about what scholarship opportunities are available and how you might qualify for one. Start the process of applying for a scholarship today!

Jumpstart Your Industrial Maintenance Career with Scholarships and Grants

Tulsa Welding School offers a range of financial aid options to help you manage tuition and start your training with confidence. Qualified students may be eligible for scholarships, and federal, state, or trade school grants.

Explore your options early and connect with a TWS advisor for personalized guidance. We’re here to help you understand your financial aid opportunities and take the next step toward your industrial maintenance career.

Program Courses for Advanced Industrial Maintenance Technology

Introduction of Industrial Facilities

AIM101

This course will introduce students to the broad history of Industrial Maintenance and the facilities of the industry, up to and including the present-day landscape. An overview of the types of machinery and control methods used to gain efficiency and drive production will be presented.

By the end of this course students will have a basic knowledge of the careers and expectations of organizations across multiple disciplines as it relates to Industrial Maintenance Technicians in the industry today.

Requirements

- 4 Semester Credit Hours

- 64 Lecture Hours

- 36 Lab Hours

- 100 Total Contact Hours

- 20 Outside Prep Hours

Safety Compliance

AIM102

This course will introduce students to the many hazardous encounters they will need to anticipate while working in the industrial workspace. Introductions to LOTO, (Lock Out Tag Out), of electrical, mechanical, potentials of energy, as well as chemical sources of energy will be conducted.

Students will explore safety related regulations and standards that are mandated by governing bodies.

Other relevant topics include; OSHA 10 standards, Confined Space mandates, Lifting & Rigging safety, Fire Awareness and Prevention, Hazardous Chemical regulations and PPE, (Personal Protective Equipment).

Requirements

- 4 Semester Credit Hours

- 60 Lecture Hours

- 40 Lab Hours

- 100 Total Contact Hours

- 19 Outside Prep Hours

Metrology & Inspections

AIM103

In this course, students will learn the proper use and care of many measuring devices. Course participants will learn to interpret and record precise measurements, while understanding manufacturer’s tolerances and suggested applications of measurements.

This course will include both standard and metric readings and calculations, as many industrial facilities use both units of measure. Dimensional inspections will be a covered topic as well.

Requirements

- 4 Semester Credit Hours

- 50 Lecture Hours

- 50 Lab Hours

- 100 Total Contact Hours

- 15 Outside Prep Hours

DC & AC Electrical Applications

AIM104

This course will introduce students to electrical theory, application and units of measurement for DC and AC electrical quantities. This course is designed to teach students electrical circuit schematics and diagrams, symbols and calculations utilizing Ohm’s and Kirchhoff’s Law. Additional concepts that will be explored are; DC and AC power generation, consumption and measuring of Direct Current and Alternating Current quantities.

Activities in this course will require students to design, calculate, build, measure and troubleshoot DC electrical circuits in series, parallel and in combination. Additional activities in this course will require students to measure and/or calculate capacitance, impedance, transformation and sine waves.

Requirements

- 4 Semester Credit Hours

- 58 Lecture Hours

- 42 Lab Hours

- 100 Total Contact Hours

- 10 Outside Prep Hours

Advanced Electrical Applications

AIM105

This course will introduce students to an intermediate level of electrical theory, application and units of measurement for AC electrical quantities. This course is designed to teach students AC electrical circuit schematics and diagrams, symbols and calculations of multiple AC circuit components as applied to 3 phase, high voltage applications.

Additional concepts that will be explored are; 3 phase power controls, modification, rectification and conversion.

Activities in this course will require students to use recently acquired skills to perform high voltage terminations, phase to phase and line measurements of up to 480 volts, as well as programming and troubleshooting various control circuits with variable frequency drives, relays and programmable logic controllers.

Requirements

- 4 Semester Credit Hours

- 55 Lecture Hours

- 45 Lab Hours

- 100 Total Contact Hours

- 10 Outside Prep Hours

Materials Processing & Fabrication

AIM106

In this course, the student will learn to identify materials, such as; types of metals, types of composites and other workable materials. The selection, safety, and proper use of tooling, power tools and standard maintenance practices will be emphasized.

The student will learn fabrication techniques through practice and demonstrating their ability to read a print, take precise measurements, utilize tools and equipment for shaping materials by cutting, grinding, drilling, tapping, bolting and safety wiring. Students will complete standard inspections and learn to document findings and order up new equipment and components.

Requirements

- 3.5 Semester Credit Hours

- 40 Lecture Hours

- 60 Lab Hours

- 100 Total Contact Hours

- 12 Outside Prep Hours

Process Technology & Facility Maintenance

AIM107

This course will cover basic principles of refrigeration, heating and boiler operations with a primary focus on industrial and commercial equipment. Students will become familiar with using computer technology and instrumentation to operate equipment systems and relate that to the industrial process. Instruction and lab activities will include monitoring operating conditions like temperature, pressure, level, flow rates, and the use of testing equipment.

This course will also test students on the intermediate level of industrial facility maintenance, as it relates to; main building power, switchgear, subpanels, distribution of power, fuses, transformers, single phase and 3-phase breakers and disconnects, automation & robotics basics, and CMMS, (Computerized Maintenance Management Systems).

Requirements

- 4 Semester Credit Hours

- 60 Lecture Hours

- 40 Lab Hours

- 100 Total Contact Hours

- 19 Outside Prep Hours

Ready to Move Forward?

All it takes to move forward is making that first step. Whether you need more information, schedule a tour or want to speak to someone, we’re with you every step of the way.

Take the First Step to Your Industrial Maintenance Career

Hear from Tulsa Welding School graduates who took control of their future.

Everyone’s story is different. Some came straight from high school. Others were changing careers or starting over. What they shared was a willingness to put in the work and a decision to pursue something more.

TWS provided the hands-on training, structure, and support they needed to move forward. Your path can start the same way. One choice. One program. A new direction.

Hear the stories of these TWS graduates and how they changed their lives:

Geicil - Welding Graduate

After moving to the U.S. from the Philippines and starting a family, Geicil knew it was time to pursue a career that could provide the future they all deserved. When her husband told her about Tulsa Welding School, she took the leap. She graduated in just seven months and landed a welding job shortly after graduation. Today, she’s a high-frequency TIG welder doing work for the U.S. Navy, a mission close to her heart with her stepson serving. She’s proud of how far she’s come and hopes her story inspires others to work hard and aim high. Hear her story on how TWS changed her life.

Michael - HVAC/R Graduate

Growing up in 1980s–90s Los Angeles, Michael faced the daily pressures of gangs and drugs. After asking himself, “Would my father be proud of the man I am today?” he realized it was time for change. While working in a warehouse, a chance moment with an HVAC technician sparked a new path, and he enrolled at Tulsa Welding School. After graduating and working as an HVAC/R tech, Michael earned his contractor’s license and eventually launched his own business. Today, Michael enjoys traveling with his son to BMX competitions and living life on his own terms. He calls TWS the launchpad for the incredible journey he’s on now. Hear his story on how TWS changed his life.

Kathryn - Electrical Graduate

As a single mother, Kathryn knew finding a work/life balance wouldn’t be easy, but she refused to settle. Despite skepticism from others, Kathryn enrolled at Tulsa Welding School to pivot away from another career that wasn’t fulfilling. The flexible schedule made it possible, and before even graduating, she landed a job offer. Today, she’s thriving in a role where she feels valued and finally has the balance to be fully present for her daughter. Kathryn credits TWS for helping her reclaim her future on her own terms. Hear her story on how TWS changed her life.