TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

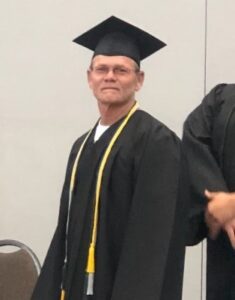

James, 58, born in Gallatin, Missouri and raised in Fresno, Texas, graduated from the Professional Welder program at Tulsa Welding School & Technology Center in Houston in 2016.

Thanks for your time, James. Tell us about your life & career before welding school.

Well, I didn’t have a career previously. I actually went to prison when I was 15 years old in 1979. I spent 33 years in prison. I got out in 2012, at the age of 48. I was always told I’d never be anything, a nobody.

Thank you for sharing that. How did you get into welding?

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

I educated myself in prison. I actually learned how to weld in prison. I lived in poverty all my life and I had to ask myself, what did I want in life if I ever got out? The answer to that question was, I wanted to be successful. I wanted to live the American Dream.

Where did the idea of welding first come from? You could have chosen another trade in prison.

I’m an artist. I’ve been drawing since I was three years old. I’m a very good, realistic artist. I do portraits, a lot of types of artwork. I was a welding supervisor in prison. I’d order supplies, make sure the production line was moving, that kind of stuff. I was sketching one day and a friend of mine said, ‘Hey, man, you’re pretty good at drawing, you’d probably make an excellent welder. Why don’t you try it? You might like it!’

Well, I had no interest at all in welding at that time, but I discovered I liked it. I learned fast, and I was actually good. I decided that welding may be the key to my success in my future if I ever got out of prison. Then when I actually did get out, I was faced with reality. What was I going to do? I decided I was going to weld; I was going to make welding my career.

New: Industrial Maintenance

Learn About Our New Advanced Industrial Maintenance Program

Tulsa Welding School is proud to announce our newest program offering available at our Houston & Dallas Metro Campuses – Advanced Industrial Maintenance Technology! Learn the skills you need to take on the industries of manufacturing, distribution, energy production and facility maintenance in as few as 7 months.

Why did you decide to come to Tulsa Welding School?

I was determined to have the American Dream, but when I got out it was a struggle because I had an X on my back. I started welding at $7.25 an hour. I didn’t have any certifications, and because of the X on my back, a lot of people turned me down. As I went from job to job at or around minimum wage, I learned it was all about being certified. I had no formal training, only what I’d learned in prison, so after two or three years of that, I knew I needed a welding education behind me. I decided I had to go to welding school. So I went to TWS in Houston and enrolled. I didn’t know that when I graduated, it would change my life financially with a great career.

What did you enjoy most about your experience at Tulsa Welding School?

I enjoyed the atmosphere, and I had some great instructors. I took it very seriously. They took the time to show me what I was doing wrong and what the industry is looking for. I paid attention to that because these guys were welding for years prior to becoming instructors. They took the time to answer all the questions I had. It was a great experience. It was worth the money. I graduated with the highest honors, a 4.0 GPA. I took my school certification and used it to open doors; I got in with good companies and got certified by the state of Texas for Structural Welding. That just opened more doors and more opportunities. Now I’m living the American Dream. I bought my own home and land. I have my own welding truck. I married a beautiful woman; I make great money. Life is good.

That’s awesome. Talk to us about the money.

I went from making nothing in 2012 to bringing home a lot of money every week, even after taxes. But there’s a myth with welding school students that as soon as you graduate, you’re immediately going to make all this money. That’s not true at all. Okay, some graduates might if they have prior experience and are brilliant welders, but you have to be determined when you first graduate. You have to put in the time, the work. You have to be good. You have to pay attention. You have to fine tune your skill as you work.

How do you get these great jobs?

The greatest impression you can make in the welding industry is how well you can fabricate and the welds that you lay down. That’s what determines your success. When a company sees that you know what you’re doing, you’re locked in. You’re on the road to success. But you have to be consistent. Every weld has to be as good as your last. You have to show your employer that you’re a reliable person that completes the assignment and job they gave you to perfection. Show up on time.

Talk to us more about that.

What we do is important. If you’re welding on a bridge or freeway, your welds have to be strong enough to hold the material together for people traveling on those roadways. Their life depends on your work. You can’t afford to have your weld break. It’s the same in the oil industry. If you’re working on oil derricks or rigs, you can’t afford to have a weld crack. Now don’t get me wrong, a weld will crack over time depending on vibrations and all the different mechanisms that put pressure on a weld, but you want to minimize the chances of that. The better the weld, the less chance of a crack happening quickly. If you want to be a successful welder, you have to dedicate yourself to the profession. It has to become second nature to you, a part of your life.

Did you work while going to welding school?

I was working for a company in Houston called Holmes Road Recycling while going to school. I’d go to work at 5:00 am, leave at 3:30 pm to travel all the way to school, and go to class from 6:00 pm to 11:45 pm. Then I’d drive an hour and a half home to get a couple hours of sleep. I did that for seven months.

That’s a tough schedule.

It’s because I wanted it. At some point not long after I graduated, I worked for a company called Weldco Industries. The owner watched me; I’d be the only one who would eat lunch and go right back to work. He came out one day and said, “Man, you really want this, don’t you?” I told him that where I go in life depends on whether I get this right or not. He’s the one who paid—I didn’t have the money at the time—for my state certification. He paid out of his own pocket for me to take the test, and he explained to me exactly how to take the test to ensure that I passed it. I paid attention and listened to him, and I passed.

That’s a great boss. You have your own company now? Do you travel?

Yes, I started my own company called Lightning Flash Welding. I have my own welding truck rig. I did some oil rig work in Casper, Wyoming, then I came back home and got married! Then I traveled to Odessa, New Mexico for a bit.

Then Tulsa Welding School called me, and they told me that they needed to see me if I was in town. Several instructors told a real estate developer that they only knew one graduate who could probably build his project for him, and they called me. At the time, I was in Odessa, working for a company named Weld Tech, so when I came home, I went in because I visit TWS all the time. They put me in contact with a real estate developer named Malcolm and architect named Kenny. They hired me to build a container home in downtown Houston. I charged a lot to weld it. It was the first container home in Houston. I got awards from the city for that.

Awesome! So, what are you working on right now?

Right now, I’m working for a company called Valley Prestress Products in Eagle Lake, Texas. I’m building these trailers that transport huge concrete I-beams out to the freeway. I actually started with their sister company, Williams Brothers Construction seven months ago. I was in their shop rebuilding these buckets that go on excavators when I was told by several supervisors that I was overqualified for their shop, and I was transferred to Valley Prestress Products.

The supervisor came in the shop and saw a bucket that I rebuilt and told me that I was too good to be working for them! He put in for a transfer. A week later I was transferred to go and build these trailers for him. I’m a subcontractor for Williams Brothers; they pay me for my truck and my machine, and I’m an employee for Valley Prestress.

What do you enjoy most about being a welder?

It’s an opportunity to meet different people from different cultures who are able to work together for a common goal; to accomplish a finished product that everybody is proud of. You can enjoy that pride, knowing that you’re a successful welder. You’ve made it from the bottom and joined an elite group.

What advice do you have for students to be successful at Tulsa Welding School?

When you’re in class, pay attention. It’s your duty to improve your life and work hard for what you want in life. Put your head in those books. Study, memorize that information. Make sure you know how to read a measuring tape that is vital. Learn how to use your tools properly. Always keep a clean area around you. Be serious, because if you’re in there fooling around, not paying attention, you’re not getting it. Do that and you’re not going to be successful when you get out. You might scrape out of school with a certificate, but if your welds aren’t good when you put them in front of an employer, it doesn’t matter that you got a certificate.

What advice do you have for graduates when they go out into the field?

You have to be determined. Trust me, you don’t know what you have until you’ve lost it all. The attitude you should have is, “I’m at the bottom, and the only thing left for me to do is go to the top.” You’re just going to have to work hard and never give up. It’s not going to be easy when you come out of school. You’re going to have to fight for it because there are a lot of welders out here and, excuse my language, but there are a lot of great welders out here.

So, I’ll say it again. You have to pay attention; learn from the instructors in school and learn from the guys you work with when you get out. Be humble, take what they show you, incorporate it into your own skills, and keep working to get better and better. The better you get, the more money you’re going to be able to make. The American Dream is alive, and it’s good.

If you’re a TWS graduate and would like to share your success and be an inspiration to others, please email [email protected] to be considered for a Graduate Connection interview. Please include details such as your graduation date (month/year), program, and campus name (Tulsa/Jacksonville/Houston).

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/